News

Kyhe Partners with Leading Manufacturer to Expand Recycled Titanium Alloy Applications

Kyhe Technology recently announced a strategic collaboration with a global manufacturing leader to develop high-end components using Kyhe DH-S® recycled titanium alloy powder. This partnership aims to scale the application of recycled materials in precision manufacturing. The partner noted that Kyhe’s recycled titanium alloy technology excels in cost efficiency and environmental performance, aligning with its sustainability goals. Both parties will jointly refine material processes and explore innovative solutions for industries like automotive and energy. Kyhe’s CEO stated, “This collaboration accelerates the commercialization of recycled titanium alloys, and we welcome more partners to build a greener supply chain.”

next

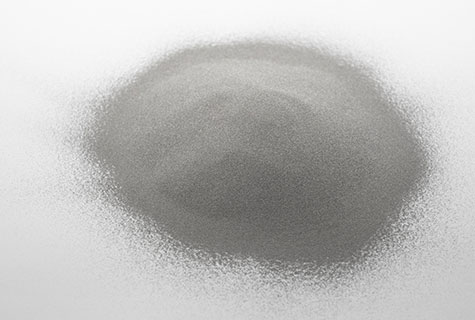

Kyhe Launches DH-S® Recycled Titanium Alloy Powder for Green Manufacturing

Kyhe Technology has officially introduced its self-developed eco-friendly recycled titanium alloy powder, Kyhe DH-S®. Utilizing advanced recycling and purification technology, this product transforms industrial waste into high-performance titanium alloy materials, significantly reducing carbon emissions in production. Kyhe DH-S®. offers excellent mechanical properties and stability, making it suitable for aerospace, medical devices, and high-end equipment manufacturing. Compared to conventional titanium alloys, its production reduces energy consumption by approximately 30%, providing a sustainable alternative for the industry. Kyhe Technology stated that it will continue to optimize recycled material technology to promote circular economy practices in advanced manufacturing.

-

E-MAIL:

[email protected] -

TEL:

+86-180 5828 5806 -

ADD:

No.66 Linbu Road, Xianxiang Town, Xiangshan CountyNingbo City, Zhejiang Province, China

Copyright © 2025 Kyhe Technology (Ningbo) Co,. Ltd.

English

English 简体中文

简体中文